- About

- Products

- Fabrication

- Services & Repairs

- Industries

- Manufacturers

- Resources

- Careers

- Contact

Lightweight conveyor belt lace – such as hidden lace and alligator lace – is one of the most popular fastening options because of its strength, durability and easy installation process; it can be installed on a belt without having to disassemble any component of the conveyor. Simply pin the ends together and you’re ready to run.

Choosing the most suitable mechanical conveyor belt lace system for your application is the most important step in the fastening process. Our conveyor belt lacing options are available in a variety of materials including steel, stainless steel, plastic, high tensile steel, and megalloy.

Belt lacing fabrication options:

Lightweight fastener options:

Your belt’s characteristics will determine which lacing fastener should be used. Belt Power created this chart to help you select the most suitable fastener for your specific application.

This chart is here to help you select the most suitable pin type for your specific application.

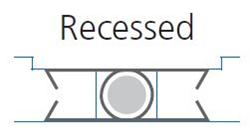

A recess fabrication is when the height of the belt is recessed near the fastener. This allows the conveyor belt lace to sit even or below the cover of the belt.

Applications:

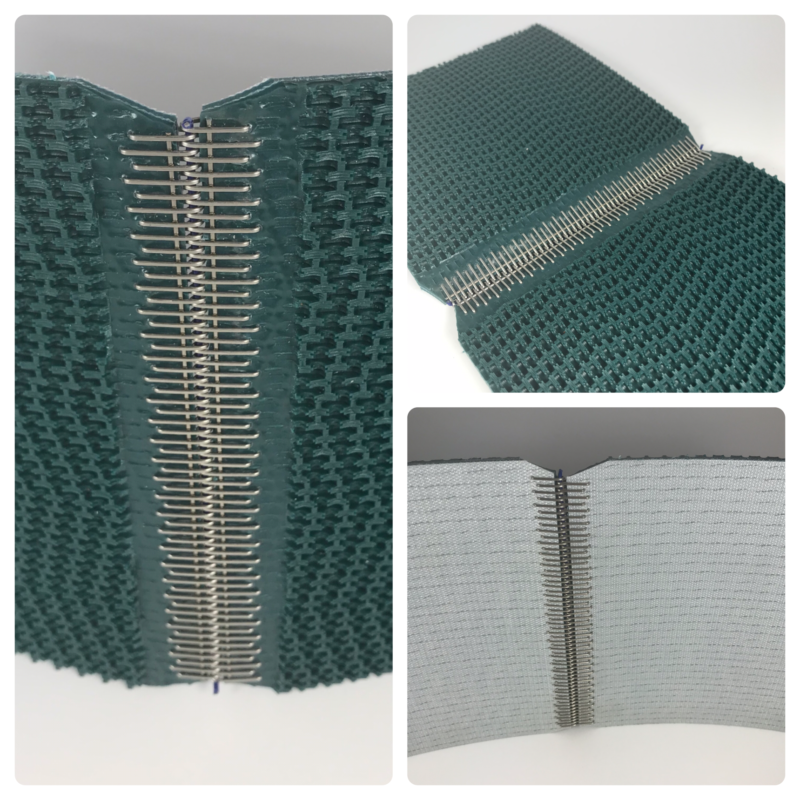

Overflap lace is similar to recessed lace in that the conveyor belt lacing is recessed below the cover of the belt, however a skim cover is left loose on the belt and covers the lace.

Applications:

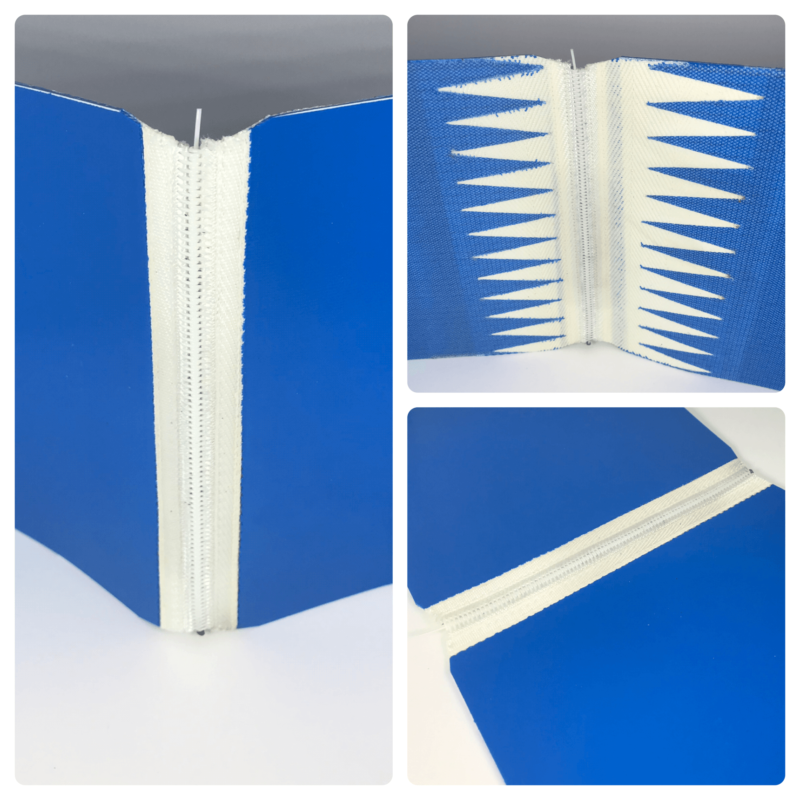

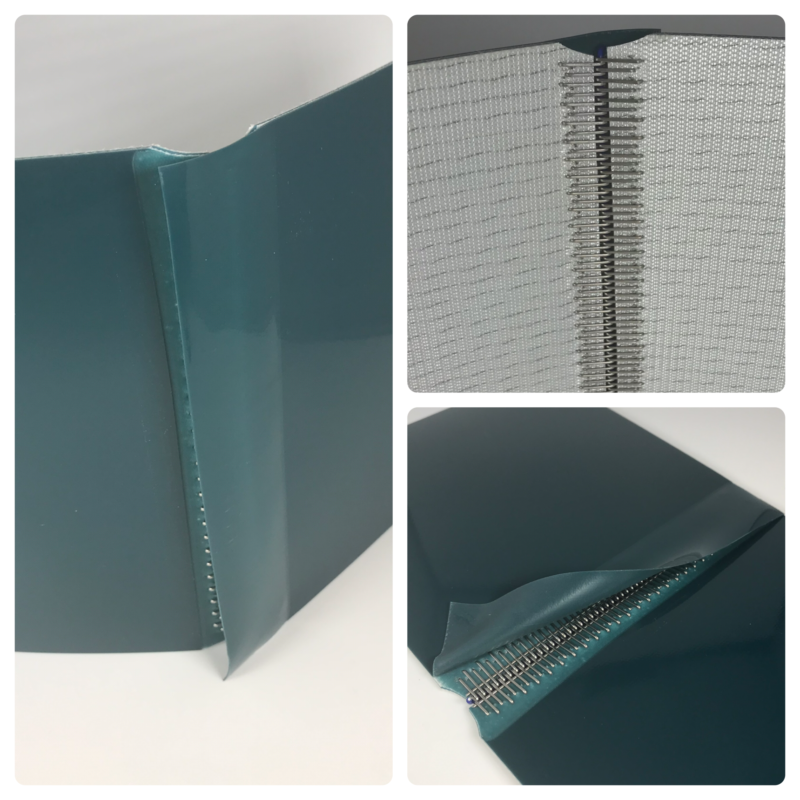

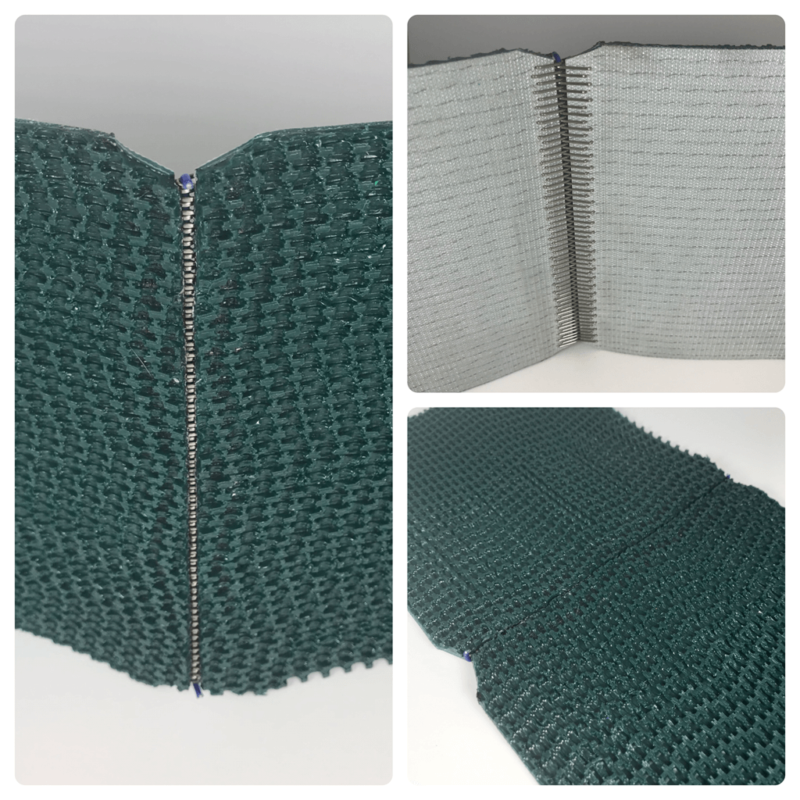

Hidden lace is similar to the Overflap fabrication, but instead of a loose piece of cover material over the conveyor belt lace, the cover is hot vulcanized in place. The top cover is then slit at the center of the lace, leaving a splice that has the looks and benefits of an endless belt, but with the added benefit of being able to separate the clipper lace.

Applications:

Conveyor belt lace can be placed on a bias rather than the standard 90˚ angle to the edge of the belt. A bias can range from 5˚ – 7˚ off 90˚.

Applications:

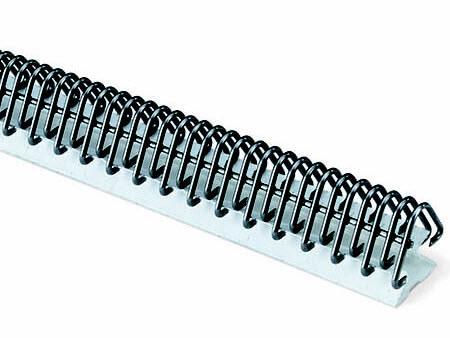

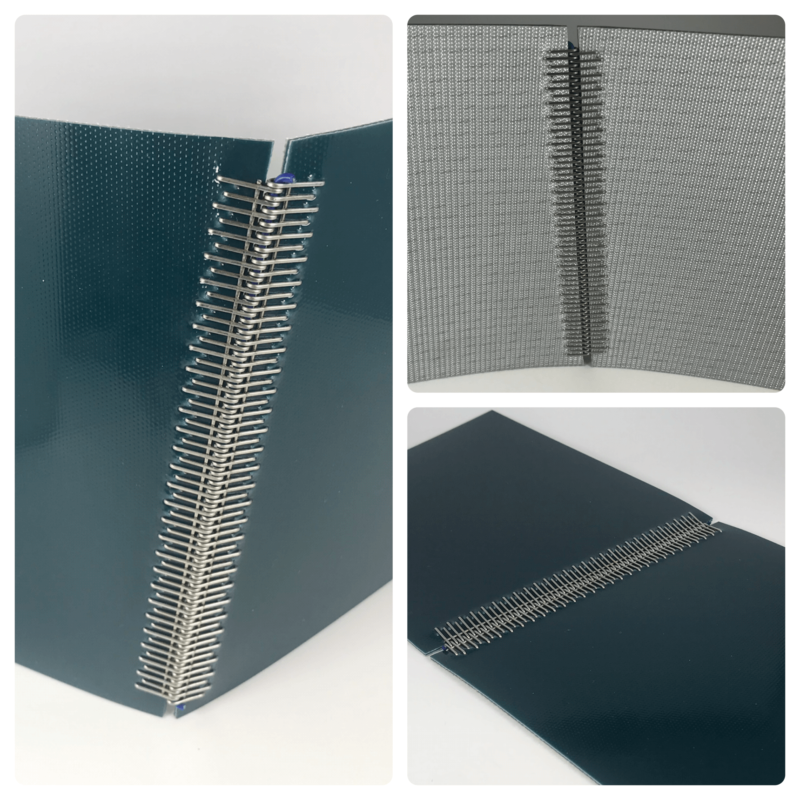

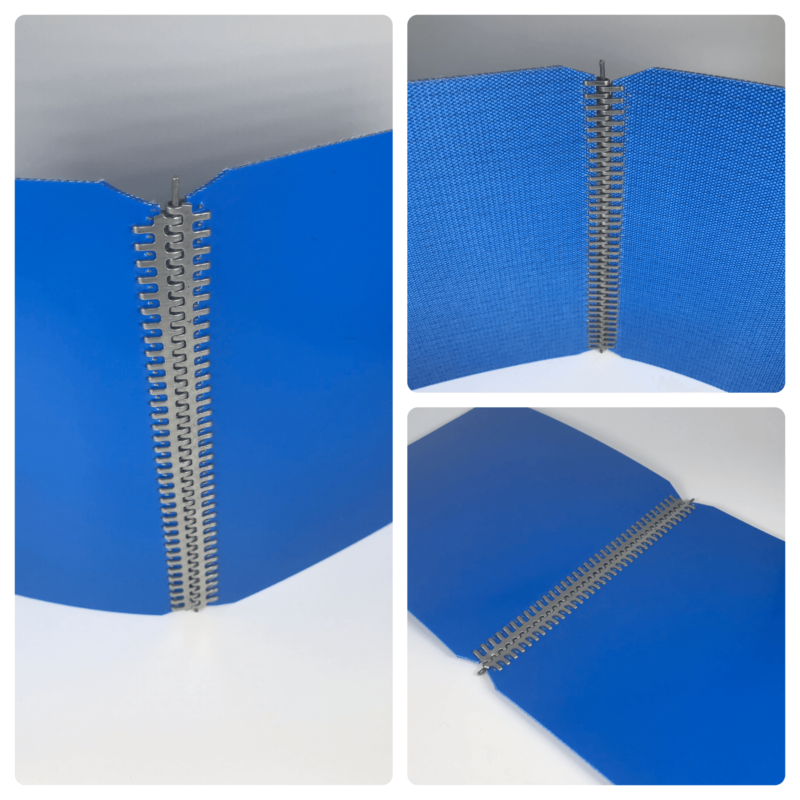

Clipper lace is the most commonly used lightweight conveyor belt fastener system for connecting conveyor belt lacing ends together. The double-staggered grip pattern gives wire hooks exceptional holding power without degrading the integrity of the belt carcass. Today’s splices also have a very low profile, making them increasingly more compatible with conveyor components and compliant with the need for reduced operating noise.

Typical industries for wire fasteners include:

Learn more about installing Clipper Fasteners® with the Roller Lacer® Gold Class™ >

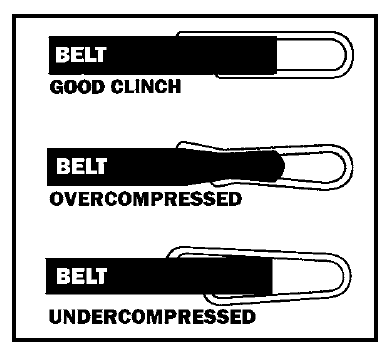

Belt is clinched correctly when the hook does not move:

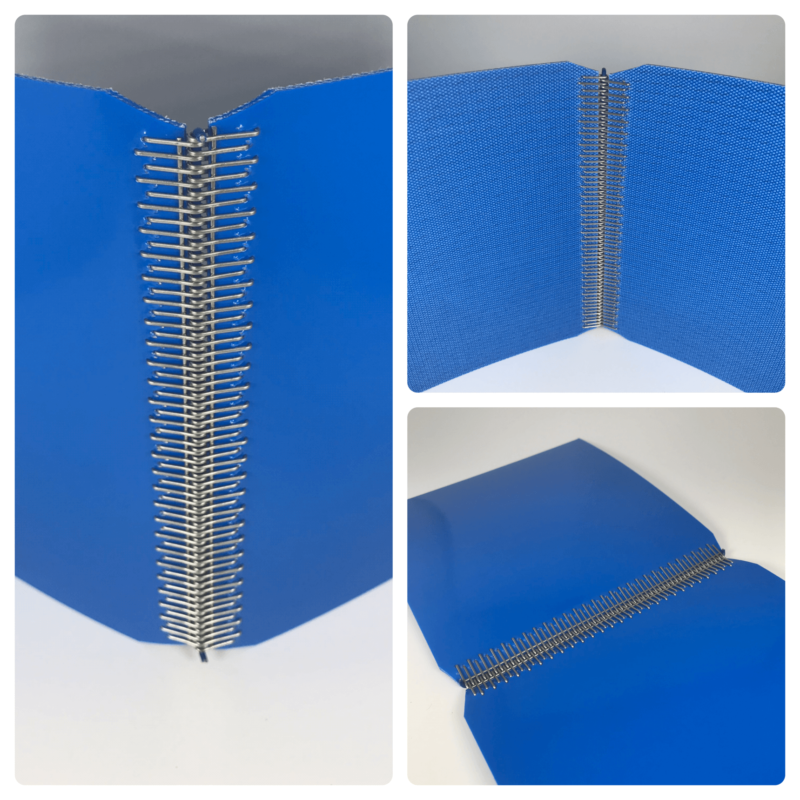

Designed for belts from 1/32” to 1/2” (.8 mm to 12.5 mm), alligator belt lacing installation requires no special tools, only a hammer. The lacing is secured with teeth that embed lengthwise on the belt, providing a strong, vise-like hold. Clips hold the gauge rod and the conveyor belt lacing firmly and squarely against the belt during the installation process to ensure a strong, straight splice. The straight splice also helps ease hinge pin insertion.

Market applications:

The Alligator® Ready Set™ Staple Fastener System is ideal for a wide variety of light-duty and medium-duty fastener applications. The system features one-piece fastener strips with pre-inserted staples that speed installation and keep downtime to a minimum. Staple lace is a more rugged and durable splice than the standard clipper lace.

Market applications:

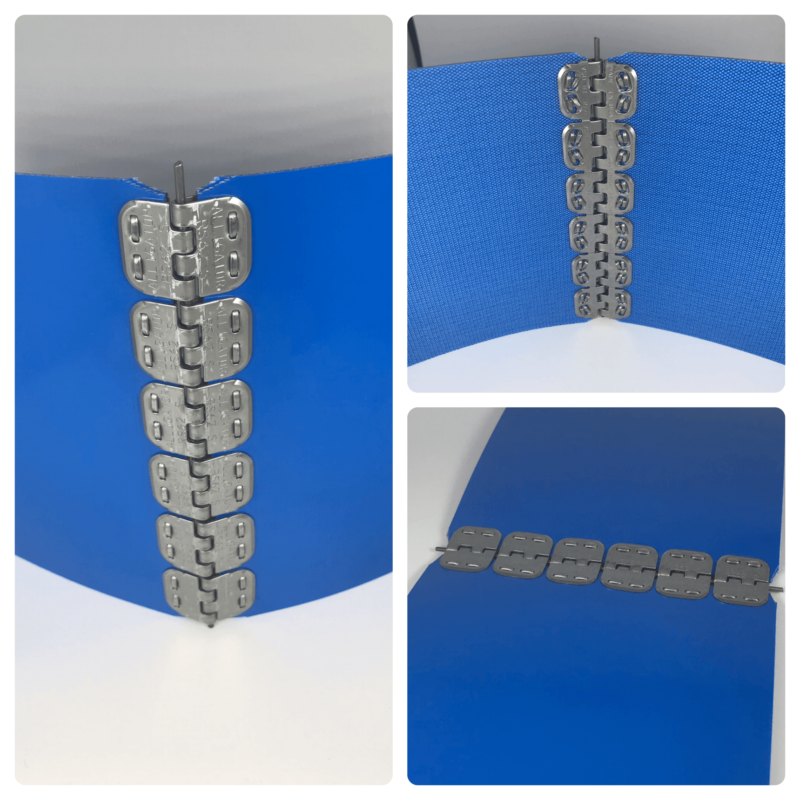

The Alligator® Plastic Rivet fastener system offers the unique ability of being mechanically installed, in addition to other non-metallic features such as: non-scratching, non-magnetic, and a quiet splice as it operates over conveyor components. The hinged splice allows for users to remove the hinge pin for easy belt cleaning or installation onto the conveyor system with minimal dismantling. The features of the Alligator Plastic Rivet system make it a low-cost alternative to the time and expense associated with vulcanization.

Key features of the Alligator Plastic Rivet fastener include:

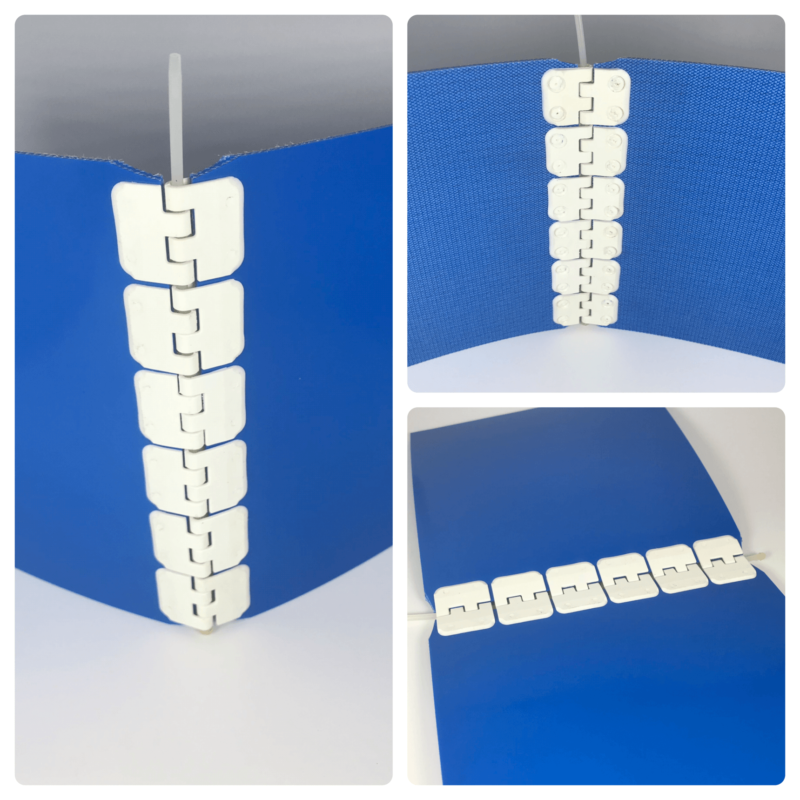

For applications where a mechanical belt fastener is desired for ease of belt installation or quicker belt cleaning, but a metallic fastener is not a viable option, consider using the Alligator® Spiral Lace. Alligator Spiral Lace is a low-profile splice that is fabricated into the belt through a variety of splicing techniques. Depending on the installation method it can operate over pulley diameters as small as 13/32″ (10 mm). It is available in white or blue polyester for applications demanding FDA-compliant materials, black polyester for general applications, or PEEK for high-temperature applications.

Spiral lace applications:

Alligator Spiral Lace is a non-metallic splice that is ideal for applications with metal detectors, food or pharmaceutical processing, x-ray equipment, or for applications with delicate product that is easily scratched and requires non-marking/non-scratching splices.